Our Sustainability Strategy

Sustainability and the Environment are dear to us all at ChargeBox. However, these are not just words; we are taking tangible actions to make our company sustainable and make the products and services we provide to our clients sustainable.

In 2021, ChargeBox committed to NetZero by 2030, which can be seen on the SME Climate Hub. Also, in 2021, ChargeBox was part of the first cohort of businesses to go through the BetterFutures+ programme, developed by West London Business, with the backing of the Mayor of London.

The mix of workshops designed by Imperial College Business School, a carbon calculator and a consultancy project focused on embedded carbon inside ChargeBox, has given us an accurate insight into our emissions and those created by our suppliers. As well as those taken on by our clients when they purchase or rent our ChargeBox solutions.

Credit: https://unsplash.com/@nrdoherty

“With the addition of a heat pump, solar thermal hot water, and solar PV, I’ve chosen to make my own dwelling zero carbon and invested in a wind farm to produce 120% of the electricity required – even while purchasing renewable energy. For as long as I can remember, I have cycled to work and back every day.” Ian

We are especially delighted to work with clients committed to NetZero. And we will provide any information and mitigations to you to help you achieve your commitments and interim goals.

Like any business, we have our emissions and waste. However, we have taken significant steps to use renewable energy for our premises and recycle everything we have to dispose of with zero landfill. These efforts really help on our Scope 1 and Scope 2 emissions. We also have a cycle-to-work scheme and encourage our staff to use public transport to support deployed ChargeBox stations.

However, we learned from our BetterFutures+ experience that our biggest challenge is to reduce our Scope 3 emissions – those we do not directly output – as they are emissions of our suppliers and clients as a consequence of providing the service. We estimate these emissions to represent over 93% of total emissions, and so represent a far bigger prize to impact than just our own direct emissions.

To provide the World’s best charging solutions, we have developed great designs and user experiences built around quality materials and leading-edge electronics. Materials (e.g. steel, stainless steel, aluminium) and computer boards, wiring, PCBs etc., all have a sustainability impact and emissions impact. Because we control those designs, we have calculated the impact of embedded carbon at manufacture and lifecycle emissions during use. We can also reduce those emissions through supplier choice, component choice, design changes, and recycling/reuse, making our solutions more sustainable.

Here are the things we’ve already done:

- Since 2019 we have manufactured all of our solutions at a UK factory, minimising long-distance logistics and ensuring control of what goes into every ChargeBox. In addition, our factory has a solar PV system that generates over 0.5MW of electricity – larger than 150 home installations.

- Our primary manufacturer works with UK and European suppliers to source primary metals and is constantly looking at ways to choose lower emissions and more sustainable materials, particularly aluminium produced using renewable energy or newer processes for stainless and mild steel.

- Because of these actions above, we estimate that around 95% by value of components and work to make a ChargeBox is kept within the UK and EU. With competitors often sourced from Asia – often from countries with high carbon electricity generation – this figure is likely the other way around for them. By keeping the value locally we help the UK economy with well-paid jobs, while also being much more in control of emissions during manufacturing. Emissions from long distance transport – usually by high emissions cargo ships are almost totally eliminated. By the time a ChargeBox reaches our warehouse – we’re miles ahead on embedded emissions.

- We have always strived for low-power components. Our Raspberry Pi main computers – also designed and manufactured in the UK – have extremely low power usage. And our other electronics means that when in idle mode and not charging any phones, ChargeBox will use as little as 6W of electricity – less than 1/10th of an old lightbulb. Our larger units with top screens idle at around 22W – still less than 1/3 of a lightbulb. Charging a phone uses comparatively little power, but 1 unit of electricity is enough to charge around 30-40 phones, 15 tablets or 5 laptops*.

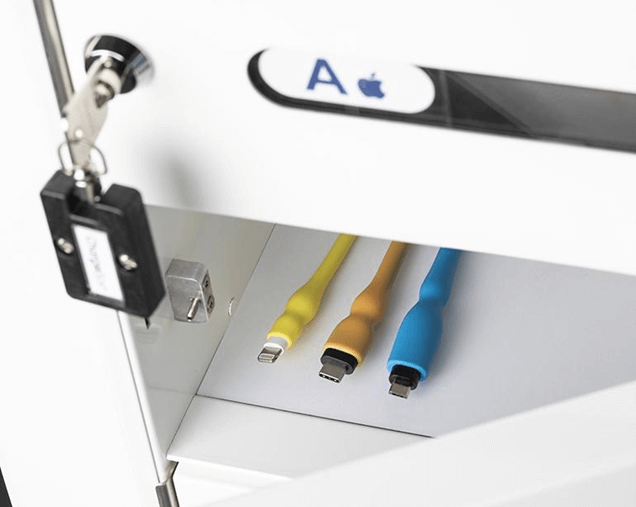

- We are on our 3rd generation of cable enhancement. A typical Apple iPhone cable may only last for 200-400 uses, but our cables last for over 4000 uses. Fewer cable changes saves materials and reduces service visits to fix while also improving availability.

- While our 3rd generation ChargeBox has the best and most reliable design ever, with almost everything changed, we have also recognised that some components from end-of-life solutions are still just as good and can be re-used. We give a lifetime warranty on these components and have reduced the embedded carbon in our latest stations by 15%. We will continue to iterate our designs and choice of materials suppliers to reduce this figure further.

- Our IT services are all cloud-based, and we use a supplier that will be carbon neutral before the end of 2025.

- We continue to work with our primary suppliers to encourage their own NetZero journey.

- We now offer to all our clients who are upgrading or retiring units to responsibly recycle, retest and reuse and can provide appropriate guarantees to clients. You can therefore be sure that metals used in any ChargeBox will be recycled, and electronics and wiring will either be re-used, repurposed, or responsibly disposed of. In addition, we are committed to incremental reductions in the embedded carbon of our solutions over their lifetime. We will also ensure they are not a burden to our clients at end-of-life.

- Many of our solutions are heavy and require complex logistics to ship across the UK or abroad. We outsource much of this to professional logistics and delivery companies. Right now, there are no suitable zero-carbon methods for moving equipment long distances, but we will continue to work with suppliers to adopt such practices when they become available.

- When we do our own deliveries, we are now trying to source lower carbon or zero-carbon transportation. This is easier around our base in London, but zero-emissions logistics for moving our heavy items around even short distances are not there yet. However, with the steps we’ve taken, we estimate that we will use 10% less carbon in our logistics emissions in 2022 over 2019, and we expect these savings to accelerate.

- We use a protective wrap on most ChargeBox solutions for permanent installation or events. This helps extend the unit’s life but is also used for sponsorship and branding. We sourced the most environmentally friendly wrap solution from 3M via a key supplier who is committed to sustainability. We also now do this in-house, eliminating shipping of panels there and back.

We are all on this sustainable journey together. We’ll be sharing regular updates and blogs about our progress. If you’re interested in our journey, follow us on Twitter, LinkedIn and Instagram to see how we’re getting on.

Ian Hobson

Founder & CEO, ChargeBox

* these are considered approximate numbers and can vary significantly between products.